A Global leader of industrial Automation Software

We provide optimal solutions that meet the requirements of the manufacturing industry based on our in-depth understanding of each industry-specific system

The chemical industry is a basic industry that contributes greatly to the development of other related industries by supplying basic materials to various downstream industries such as electronics, automotive, textile, aircraft, and fine chemicals, and is divided into petrochemical industry (based on dismantling and polymerization of petroleum products to produce and sell synthetic resins, chemical fiber raw materials, synthetic rubber, and oil products) and non-petrochemical industry (distilling, decomposing and polymerizing other natural resources than petroleum to produce and sell basic material products). In recent years, it has been shifting from playing the traditional role of supplying basic materials to creating high added values from high-tech goods such as semiconductors, FPDs, batteries, and encouraging technological innovation.

Therefore, as entering the market with new product lines and product development through R&D for this purpose have emerged as a hot topic of the chemical industry, production requirements need to be met no longer by the traditional mass production of single products but by multi-product production, and this subsequently generates a need for breaking out of the traditional industrial characteristics of operations based on site facilities and devices in order to meet the requirements of centralized production control, product and material visibility, global integrated quality control, linkage with capital intensive equipment, and linkage with SCM.

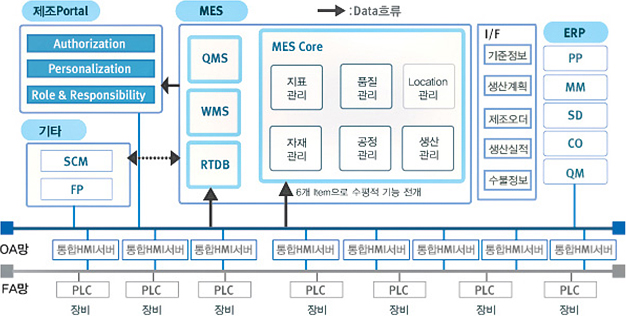

| MES | Production Control - PO, WO, Input/Production report control, etc. Process Control - Lot history management, Process monitoring, etc. Facility Management - Facility information change, Environment control, Equipment control history, etc. Material Control - Work In progress, Shipment, Material movement control, etc. Basis Information - Yield, Productivity, Nonconformity rate, Return rate, etc. Index Control - Production daily/monthly log, Production progress history, Log sheet, etc. Report - Quality/Import inspection control, Real-time monitoring, Defect inspection, etc. |

| QMS | Quality Control - Quality/Import inspection control, Real-time monitoring, Defect inspection, etc. |

| HMI | Process Equipment Monitoring - Providing source data to MES, QMS, and RTDB, and automatic reporting of goods receipt and payment information |

| RTDB | Fine Process Control - Fine process monitoring, Process trend & Lot trend, Process error history control Batch Trend & Histogram - Possible to compare process variables for individual batches (lots) |

| WMS | In/Out, Inventory Control - Warehousing control, Movement control in warehouse, Inventory control, Releasing control |

| WMS | Link to ERP - Production schedule, Warehousing, Input, Production report & Material movement in process report Link to SCM - Finished product shipment history |

The chemical solutions provided by BECOME SOLUTION Co., Ltd. are integrated production information system solutions which present business process models suitable for chemical processes and offer an optimum visibility interfacing production plan, production process control, process quality control, material input control, and finished product shipment.

Cheil Industries Electronic Materials, Cheil Industries EMC, GS Nanotech, KCC